Bentonite

Bentonite

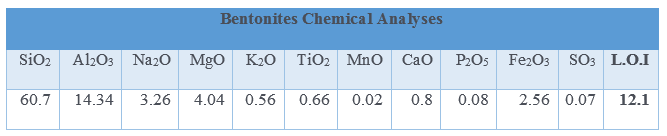

Bentonite is a clay consisting mainly of smectite minerals, commonly formed by decomposition of volcanic ash or tuff, or sometimes from other igneous or sedimentary rocks. Bentonite is a very plastic clay that shrinks (or swells) markedly in response to the removal (or addition) of water.

Bentonite is classified into two types, sodium and calcium, based on sodium and calcium impurities.

Sodium Bentonite or Sedic Bentonite: Bentonite whose mold impurity is sodium element and absorbs moisture and expands to a large extent due to water absorption. Its main use is in drilling oil and gas wells and it is also used as a natural insulator.

Calcium bentonite: this type of bentonite has high calcium impurity. It is an ion absorber in solutions and is used for deionization. Unlike the sodium type, instead of absorbing water, it can absorb fats and oils, so it is used as an industrial detergent in manufacturing industries.

Bentonite can have different applications based on its special physical characteristics. The important thing is that bentonite that can be used for one industry is not necessarily usable in another industry.

Applications

1- Use in earth wells:

Bentonite has little resistance to electric current and has thixotropic properties, therefore its slurry is used in the construction of earth wells and to fill around electrode rods and is a cheap substitute for coal and salt in earthing systems. Is.

2- Use in oil and gas well drilling industry

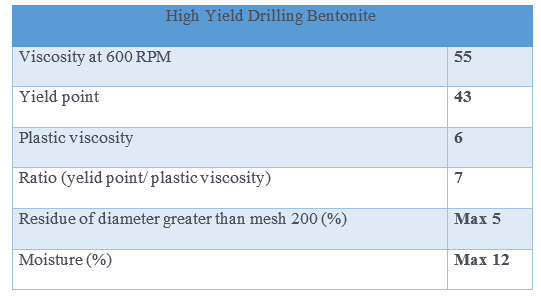

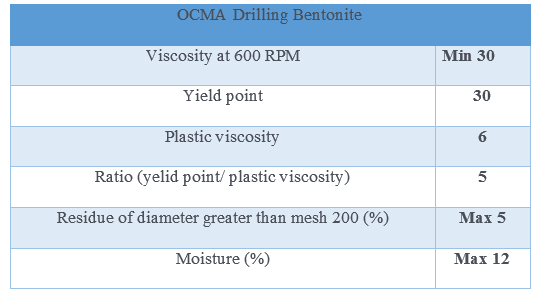

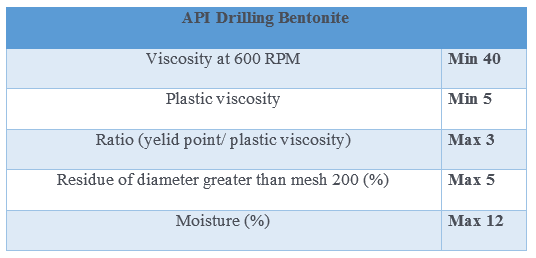

Bentonite is widely used in the oil and gas well drilling industry. Bentonite used in oil and gas wells has a certain standard, which should be mainly under API standard or OCMA standard. For this reason, bentonite drilling is known according to the standard type. Bentonite has a very high water absorption and is known as a viscosifier. and increases the viscosity and viscosity of the drilling fluid. Increasing the viscosity of the drilling fluid helps maintain the structure of the fluid. Also, a stable layer should be created in the wall of the well to stabilize the well and the pieces of drilling cuttings will remain in the fluid and be directed upwards.

Bentonite has a very high water absorption and is known as a viscosifier. and increases the viscosity and viscosity of the drilling fluid. Increasing the viscosity of the drilling fluid helps maintain the structure of the fluid. Also, a stable layer should be created in the wall of the well to stabilize the well and the pieces of drilling cuttings will remain in the fluid and be directed upwards.

There are other parameters in the API standard to determine the quality of bentonite, such as yield point and filtration, each of which has certain values in the standards. Drilling bentonite is usually packed in one-ton jumbo bags.

3- Use in pelletizing

Due to its stickiness, bentonite is also used in pellet making, and it is combined with iron concentrate and then baked in a furnace to produce iron pellets.

4 – animal bedding

Due to its very high water absorption, bentonite can absorb water and animal pollution well, and for this reason, it is used for the bedding of animals such as cats